- Sets and resets seamlessly

- Holds well in mud. Not as good as Fortress, but better than anything else.

- It does NOT clog with sticks and sticky mud like roll bar anchors. This is a big win in the Chesapeake.

- Does well in hard sand.

- Aluminum. 8 pounds is all I need! But steel would be even better in some ways, so get steel unless ounces matter to you.

- Comes up clean, like a Delta. But it sets 4x faster and holds 2x better.

Before testing, I had not yet fitted a rode.

I like it!

Update, 7-11-2020

Rocks seem to be the Achilles heel of well, every anchor. I spent a number of days last week fishing some areas over jointed rock slabs with small pockets. The best anchors are those that present a sharp point straight down. Northill is quite good. Steel pivoting fluke anchors are surprisingly good. Everything else is terribly hit-or-miss and insecure with even the slightest shift. Very long scope is the rull, since ANY uplift will cause intimidate dragging.

Thus, my standard anchors will now be the Northill and the Excel. Both hold well in sand and mud, and the Northill will fill my fishing needs.

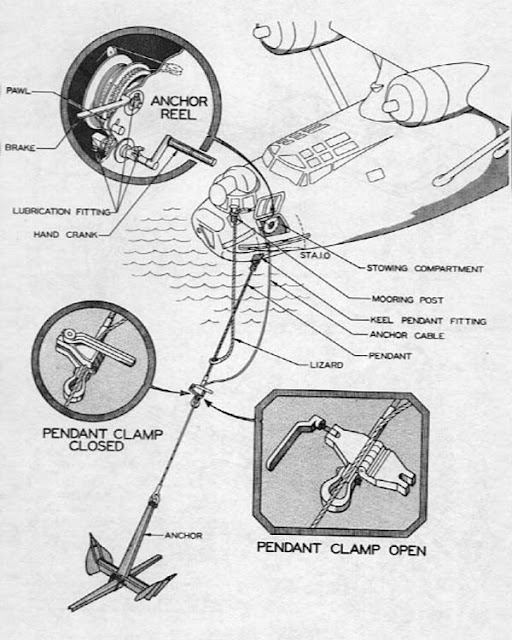

So where did the Northill design come from? They were used to anchor flying boats in WWII. Not this specific model. There was a light weight stainless version. But the same angles.