(Note: I will be revising this as I get dimensions and finalize the design)

rev. 10-12-2015

("have" indicates I somehow have on in the might-need pile. it is a substantial and rich pile, scavenged from far and wide. It really helps keep my boat keeping cost down. My sources, of course, are top secret.)

After a day at the boat show and talking with designers, I've become convinced the real reason for a bowsprit on a cruising cat is not speed, it is to prevent hourglass tangles during jibes, the result of the forestay and spinnaker tack being too close together. My Stiletto tangled, my Prindle never tangled, but the PDQ will do it every time if the lines aren't handled just so. I could lower the squeezer, jibe, and rehoist, but that just isn't cool. And thus, a bowsprit is in order.

I'm not interested in a screacher; I have a 150% genoa that provide nice

balance and is all she really needs or want up wind. This is only for a

chute. Thus, I do not have to design for the huge tension loads a stay-set sail requires.

I cannot use the pole-type that Sandy (PDQ 36

Page 83) used;

there is a gull striker in the way. I wouldn't want it over the tramp

anyway.

Water stays. I can't secure them to low mounted u-bolts in the conventional manner; the starboard side the crash tank comes up at least 18 inches. Mounted that high, the compression load on the front beam would double, and I don't want to add a compression strut to the bridge deck. I could rig them like the Gunboat G4 and most beach cats:

- Stays to the fore beam ends for lateral loads.

- Extend the gullstriker downwards (dolphin striker) ~ 18" and run a stay

from the tip of the pole, under this striker, to an anchor on the bottom

of the bridge deck. This will take the vertical loads. However, the compression load on the front beam is doubled.

So long as I can take the water stays near the water line, I'm not too concerned about the aft load on the fore beam for a chute. Some simple capsize calculations suggest that the maximum tack load might be about 450 pounds, though the usual load is less than 250 pounds even at double digit speeds (I can hand-tension the 2:1 bridle with reasonable effort by snapping it up so long as the wind is aft of the beam). The lateral load, whether carried by water stays or beam stays, results in only about 120 pounds of compression on the sprit. The vertical load is the concern, resulting in about 320 pounds of compression. Though I do not have detailed information on the forebeam, 440 pounds doesn't strike me as a lot on that span, far less than hard jumping on the tramp, which won't be happening if you are driving that hard.

Another way to think of this is to convert the force to horsepower. twin 9.9s can generate about 400 pounds of line pull (tested). If the tack tension is at 450 pounds (parallel to our direction--no drive), the sheet tension is generally about 500 pounds and the forward component of the halyard tension will be about 400 pounds, for a total of about 900 pounds of drive from the chute alone. Assuming about 1/2 that from the main and we have 1350 pounds of drive, or 67 horsepower. 3.3 times usual and enough to be driving in the low-teens. That would require over 25 knots going deep or 20 knots closer to the beam and is off my speed polar (I wouldn't drive nearly that hard as a hull start getting light--I've done that).

I will make the up-haul tackle internal, fed to one of the jammers.

So how to secure them low? I plan to use the same method I used on my Stiletto. I will take a stainless strap, like a chain plate, and wrap it around the bow at he height of the boot top, hiding it under the tape. It will be secured by about 8-10 self tapping screws in solid FRG, well bedded with polyurethane (Locktite PL S40 from Home Depot is a steal). Since all of the stress is in shear, they are safe and well suited to this application. I would go a few inches higher to reduce drag, but I want to hide it and I need to stay in the solid glass. The water stays themselves will be 3/16" Amsteel (have).

The spar itself may be a Hobie cat mast section (have), though that is overkill and I may switch to something smaller, If I find it. Smaller would save a few pounds, perhaps, but the larger diameter and thichness will make mounting the jammers easier.

There will be 2 internal lines; 2:1 tackline and 2:1 uphaul to the top of the gull striker (this supports only the sprit, about 8 pounds). These will be secured to jammers (have) on the sprit (I have these). I will put loop handles on the ropes to make hauling easier.

The tackline will exit through a Stiletto reacher halyard bock (have). The uphaul through a smaller block.

The slider is visible on the beam

The lines will be 8mm nylon (have). I reason the uphaul needs some stretch, since the water stays will not and any boats twists a little, moving through the waves. I don't want to create excess stress on the gull striker or forebeam by virtue of an unyielding rig. The spinnaker tack line will be polyester; stretch is not a concern--spinnakers need some give in lumpy conditions--the length is very short and it is 2:1 purchase.

The butt of the pole will rest on a track on the fore beam, allowing it to be moved to the side using a pin slider (have). This is NOT for adjusting the sprit, but rather to allow folding. I will likely not fold the sprit for years at a time, but they are commonly designed this way to allow for attaching and detaching furling screachers. Since I have the parts, it makes for a convenient mounting.

Not folded this way, but that is the idea. I doubt I will fold it often, perhaps not every year. but worth providing the option, since it also allows height adjustability.

Angle. Level or canted upwards. Level minimized compression on the sprit. Canted upwards improves control of the tack and reduces sail bouncing in lumpy conditions. I suspect I will tip it up about 1-foot, but it will be adjustable.

What will I need to buy? Embarrassingly little, for a professionally built and equipped sprit nearly identical to that on the Antares 44. Perhaps a few few pad eyes and a few screws, though I may have them. I may have to buy the stainless straps. Kits are available for ~ $1200 + rigging, but I bet I can do this for

less than $50, the track being the major expense, using my considerable

"might need" pile. I'll keep track. I will get the sprit I want and a

few custom features.Not much, lunch money should cover it. Neat.

Thoughts?

rev. 10-12-2015

After a day of measuring, looking at the speed polar, and considering the way I sail, I've decided the sprit is not nearly as versatile and efficient as the bridle:

- We use the chute with the wind on the quarter, going deep, more often than on the beam. The purpose of the chute is to provide speed when too deep for the genoa.

- The bridle presents more area to the wind, when shifted to windward, going deep.

- The bridle provides better tack control (height and less bobbing in lumpy conditions).

- The bridle weighs less and creates no drag.

Jibing remains a problem, but how often do we jibe? Not most days, and then perhaps only once. The ability to go deeper gives better VMG and reduces the number of jibes

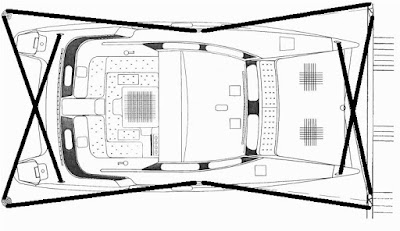

The current set-up looks like this: