22016, Rev. 7-30-2024

In the spring I enjoyed posting a rant about the 7 sins of spring boat work. However, either not all sailors read this blog and follow my sage advise, or perhaps I simply need to these few items to my growing list of obvious time wasters.

1. Pulling halyards and replacing with messenger lines. Let's look at the case of a typical 45-foot mast:

Capital. 4 halyards x 90 feet x $1.30/ft = $468. Of course, these will last 8 years anyway, so perhaps hiding them for 5 months will stretching that to 10 years. We'll save $117.00 over 8 years. We'll need messenger lines; I'll give you a discount and assume that most are old halyards, so only $150.00, or a $33.00 loss for our efforts.

Labor. If we are very efficient, it takes us 1 hour each way for all 4 halyards, or 16 hours over 8 years. -$33.00/16 = -$2.06/hour loss. If all the messenger lines were free (and I have watched people buy them) you would have earned $7.31/hour. Whoopee. And I bet that won't seem like much if just once in 16 x 4 = 64 cycles, your stitching breaks free and the line goes to the mast head and back down to the base.

Those messengers need stored and to be hauled to home and back. More work.

Perhaps the most obvious flaw in the practice is that the lines need not wear at the same points in the winter that they wear in the summer. They can be shifted by simple means: the roller furling jib will be lowered, the topping lift can be raised 1-foot, and the main and spinnaker halyards can be extended 1-foot to hide the normal wear points; pull them out a little further and tie them to the rail instead of clipping them on. That will take only minutes in the fall and seconds in the spring. With simple practice, I suspect the lanes will fail first at one of their normal wear spots and all of the effort of storing the lines will have been for naught. Good exercise, I suppose.

Perhaps they are high-tech lines on a tricked-out "racing" boat. Though she may have Kevlar sails, she's an over weight monohull and pretending to race is rather like a whispering contest. Real race boats can go 20 knots. They have 2 or 3 hulls or or flat bottoms. One designs race too. Handicap racing, particularly hauling lead and cookware around sheltered waters is plain silliness, in my not altogether humble opinion. I feel the same about bowling and golf too, by the way; really, you either win or you don't. Age and weight classes I get.

On my last boat I got 10 years out of my Kevlar halyards, and they are anything but durable. I simply trimmed them a few feet every few years.

See also Reeving Eye, below.

2. Hauling for the winter. My last boat was seriously damaged by improper blocking. Really, how many boats are better supported on stands than by water?

Freeze damage is a lesser risk in boats in the water, since the temperature very seldom dips below freezing; the water keeps them (relatively) warm. Every spring I see a few rudders and keels that have been split by ice while stored on the hard; they've seen temperatures they would never see in the water. Yes, you need to be sure of your through hulls and drains.

Off-season sailing. Anyone who would willingly miss the Chesapeake in October shouldn't call themselves a sailor; it's the finest season. Additionally, the cost-per-sail is half when you sail twice as much, or nearly so. Spring commissioning largely goes away. Engines and electronics prefer regular use.

Expense. About $325 to haul/block/launch. Another $1,000 in storage. A total waste. Yes, hauling for painting is unavoidable, but there are plenty of 2-year paints, and that only takes a week.

Insurance. No, hauling is not required and staying in increases rates only about $50/year (they know yards aren't safe places). You are typically required to "lay-up" for a few weeks (the specific weeks are designated in my policy), but that can be in the water. The only requirement is that "the boat not be available for immediate use", which is simple to document in the log. Don't be dumb enough to have an accident sailing during the designated week.

3. Taking everything home, for safe keeping. Thanks, but no thanks. I've got enough stuff at house. My marina is safe--in over 20 years nothing has moved on anyone's boat.

4. Extra lines, but no chafe protection for those they already have. Would you rather have one good climbing rope or 2 ropes that were pulled up from the ooze under the marina?

5. Tarps. Yes, they can help, if well thought out. I've also seen gelcoat rubbed to bare glass, stanchions pulled in, biminis crushed flat, and stands pulled out (the high-wind domino is always a fright to see). Invariably, they blame the damage on the winter, not the tarp. I'm very judicious in my use of tarps.

__________________

I simply feel better knowing that my toy, my alter ego, my escape, is in a continuous state of readiness, to go where I want and when I want. Any illusion of freedom requires that.

But humans are herd animals; if we see a group, we follow the crowd.

_______________________

Reeving Eye

If you are going to pull your halyards, imagine the things that can happen if your tape, thread, or paper clip splice comes apart:

- The reeving/mousing line falls to the ground, the halyard goes to the masthead, and you have to climb and get it. Annoying or bad, depending on your skills.

- Both lines fall to the ground. You will have to climb and tread a new line down the mast, not snagging anything or placing the line where it will chafe against wiring and anything sharp. Much worse.

- The reeving line falls to the ground and the halyard collapses into a piling inside the mast, tangling and wrapping around fasteners, wiring, and through-bolts. This can take days to sort out, if you can sort it out. You'll want to sell the boat. If you contract it out, it can cost thousands.

Instead, connect the halyard to the reeving line with a reeving splice. Do it right.

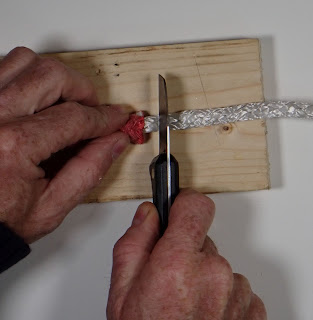

- Remove about 8-10 inches of core. There is no need to taper it, just cut it square. Milk the cover back out until it extends 8-10 inches beyond the core.

- Make a very small eye from the cover by burying it back into itself. You don't need a fid, just a length of rigging wire bent into a tightish hairpin. Ideally, the buried cover touches the end of the truncated core, but this is looks not function. Lock stitch to keep it in place. The eyes should be 30-50% line strength, depending on the details. Very strong and no larger than the line itself.

- Lash the two lines together with heavy whipping twine.

As a bonus, the eyes will be there next year AND there is no need to whip or otherwise finish the line ends.

Another possibility is to simply stitch the cover flat against itself. Just as functional.

I'll post a video on sewn eyes as soon as I find it. That's a slightly different thing, but it is often the only way to splice a used line.